dynamically porous materials for molecular separations

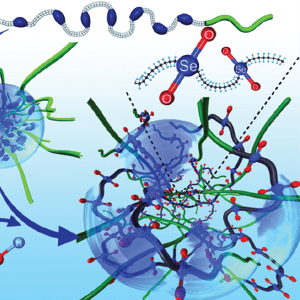

Polymers of intrinsic microporosity (PIMs) exhibit an interconnected network of molecular voids resulting from the shape and rigidity of the component macromolecules, and have been most often used for gas adsorption and separation. In collaboration with the chemical engineering labs of Ryan Lively and Bill Koros, the machine learning laboratory of Rampi Ramprasad, and with colleagues at ExxonMobil, our lab is investigating novel monomers and modes of connectivity for developing new PIM-style polymers for molecular separations. It turns out that molecular rigidity is not the only property that is important. We have learned to introduce controlled dynamic motion to achieve unprecedented separation of the components of petroleum using membranes rather than distillation, which can save enormous amounts of energy. We are also developing new methods for post-polymerization modifications and seek to gain predictive understanding of how the polymer structure affects separation properties in complex mixtures.

degradable hydrogels for drug and vaccine delivery

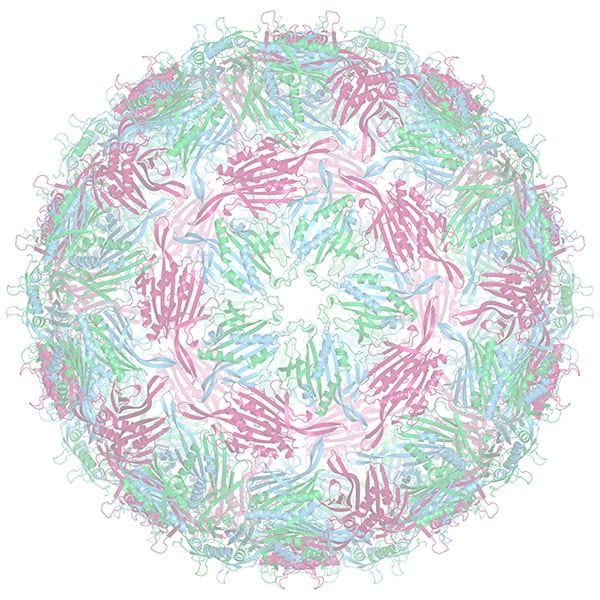

Hydrogels are the most useful class of materials for the delivery of functional molecules to biological systems. Oxanorbornadiene (OND) and azanorbornadiene (ZND) chemistry provides the most widely tunable type of connection known for the controlled assembly and breakdown of such materials. The prototypical example is provided by the Michael addition of thiols to O/ZND electrophiles, a fast click reaction that assembles gel materials at rates controlled by either the buffer pH or ionic strength. The resulting material then contains the seeds of its own destruction, as each bond made turns on the clock for cleavage of the link by retro-Diels-Alder reaction. By incorporating different OND variants, we can control the fragmentation rate over many orders of magnitude. This technology then provides a unique and generalizable process for making degradable materials. For example, we have made hydrogels from dextran-thiols and multivalent O/ZNDs with polyethylene glycol (PEG) arms. These gels form rapidly at room temperature, whereas their erosion can be programmed to occur in minutes, hours, days, or months. We focus on biocompatible degradable network materials with potential applications in regenerative medicine and sustained release.

Functional Particles and Surfaces

Click chemistry methods are well suited to the modification of surfaces. We use these reactions to modify the properties of silica nanoparticles, polymer nanoparticles, 3D-printed polymers for medical devices, and medical tubing. Target properties include antimicrobial activity, surface wettability, covalent integration into polymer networks, and controlled binding to cells and biological materials. Our collaborators in using the resulting materials include Children’s Healthcare of Atlanta doctors, materials scientists at Georgia Tech (Blair Brettmann, Jerry Qi), and biomedical engineers (Scott Hollister).