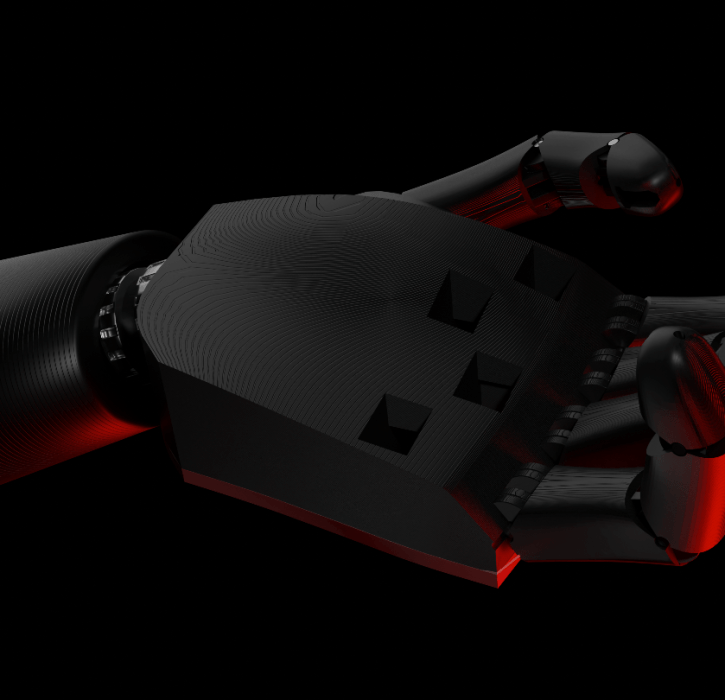

Team Limbo’s goal is to create an affordable biomechatronic prosthetic arm and hand for trans-radial amputees. Our project focuses on controlling the prosthetic device through analyzing electromyography (EMG) signals with machine learning models. Our design also aims to integrate an array of sensors and a functional haptic feedback systems in order to simulate a sense of touch for users. Finally, by incorporating custom 3D printed components created through computer-aided design (CAD), our team will be able to lower the total cost of the prosthetic, increasing the accessibility and affordability of the device for consumers.

Mechanical Team:

- Modeled and 3D printed prototypes for finger and palm designs

- Developing two competitive designs for our finger mechanisms

- Integrated motor into designs

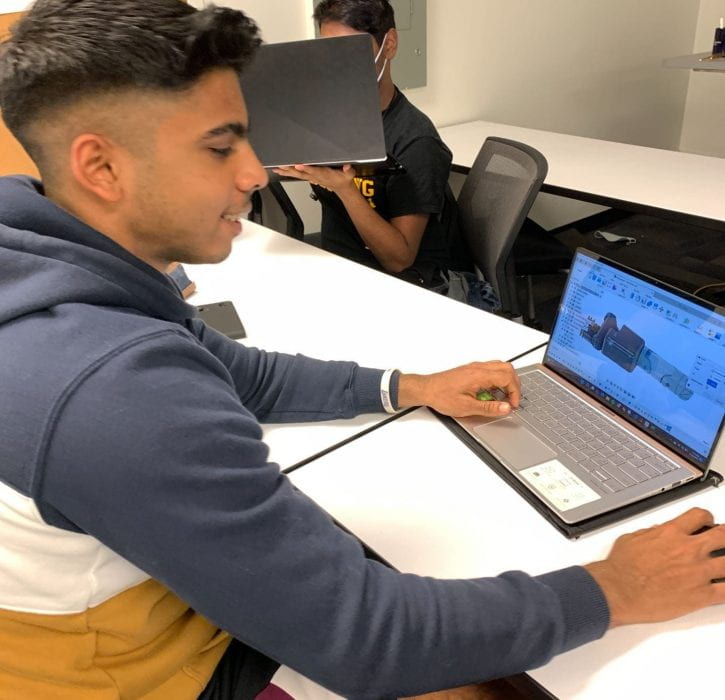

- Makes CAD Models using Fusion 360

Electrical Team:

- Slip sensor PCB and C++ code created

- Servo lever arm CAD designed

- EMG filter SPICE simulation and working breadboard prototype

- Integrate force sensor into slip sensor PCB

- Design EMG sensor to gather signals from multiple electrodes

- Create sensory feedback wearable

- Design power management circuitry for portable Li-Po battery power

- Create low-profile microcontroller PCB and C++ code to control electronics on the hand

Software Team:

- Collected, stored, and organized EMG data

- Set up a method to preprocess data

- Created a binary classifier to recognize opening/closing of a hand

- Researched and began implementing LSTM as a network architecture

- Uses Python and Pytorch for Machine Learning Models