Motor Thermal Management:

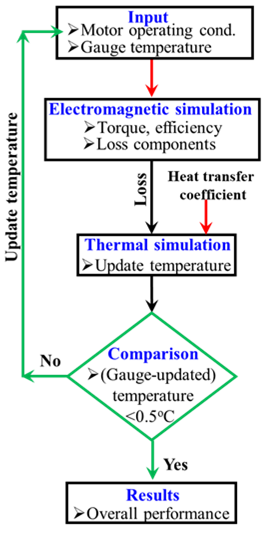

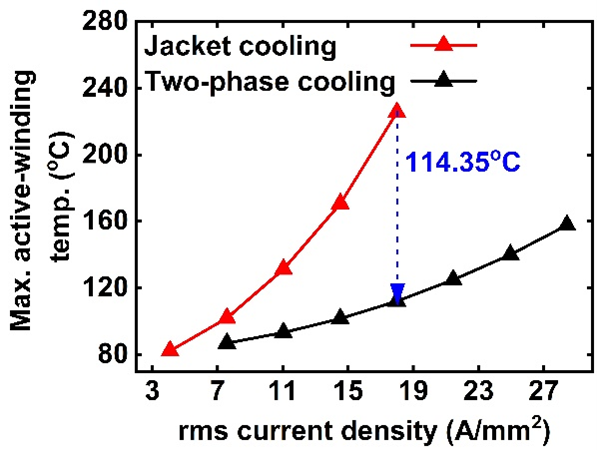

Permanent Magnet Synchronous Motor (PMSM) are broadly used in electric vehicle (EV) and hybrid electric vehicle (HEV) applications because of high power factor and torque density. However, high heat generation in the motor as a consequence of copper loss, stator and rotor core losses often reduce the efficiency, and longevity of the electric motor. Finding appropriate thermal management system for the electric motor, in order to enhance the power density and efficiency by maintaining motor temperature below the operational limit, is a major challenge to thermal designer. To develop appropriate heat rejection techniques, first benchmarking approach should be the accurate quantification of component-wise electro-magnetic heat losses and peak temperatures in an electric motor. In order to accurately predict electro-magnetic performance, i.e., efficiency, component-wise heat losses and the corresponding temperature distribution, we develop a two-way iteratively coupled electro-magnetic and thermal modeling framework. Based on the hot-spot distribution of the conventional liquid cooled motor, we propose a novel concept of latent heat driven evaporation abetted two-phase cooling technique to remove heat from the hot spots. Numerical fully coupled electro-thermal analysis has been carried out to quantify the effect of evaporative cooling on the overall motor temperature distributions. The numerical results illustrated that evaporative cooling can remove significantly high heat compared to the single phase liquid cooling and thus, maintain the motor temperature in the maximum allowable temperature limit of the motor. We also develop optimization algorithm for further modification of the evaporative-assisted cooling system by utilizing system-level modeling environment and machine-learning techniques.

Fig. 1: Two-way coupling framework

Fig. 2: Steady-state maximum active-winding temperature vs. rms current density for jacket cooling and our proposed advanced cooling.

In order to avoid early breakdown or permanent damage of the traction motors, it is essential to monitor real-time temperature variation of different motor components. Although the CFD/HT model can accurately predicts motor temperature distribution, CFD/HT model is computationally expensive. Therefore, we have developed a highly discretized 3D lumped parameter thermal network (LPTN) model to monitor real time motor temperature variation. LPTN model has also been successfully used to accurately predict electro-thermal performance of a 125kW BMW i3 motor topology for two-phase cooling application.

Fig. 3: (a) 3D LPTN model layout for jacket cooled BMW i3 motor, (b) comparison between jacket cooling and two-phase cooling over a custom drive cycle

Thermal Management of Micro-electronic Devices:

The exploration of ultrathin thermoelectric coolers (TECs) on the active side of microelectronic devices for the energy efficient thermal management of hot spots is another thread of our research. Our research analyzes the efficient usage of ultrathin TECs by focusing on important issues such as integration of these devices with electronic package, effect of parasitic contact resistances, utilization of appropriate current pulses and control algorithms. The study extends to analyzing coupled operation of multiple TECs for cooling spatiotemporally varying hot spots in order to maintain the dynamic hot-spot temperature below a threshold.

Fig 4. Temperature contour in a vertical cross section of electronic package. (a) Temperature contour with 0 A current through all four TECs. (b) Temperature contour with 1.75 A current through all four TECs.

Thermal Management of Portable Electronics:

The constant miniaturization of the electronic components and the increasing use of mobile devices has pushed the limits of the current solutions to deal with thermal management of portable electronics. 2D materials with high in-plane thermal conductivity, such as graphene and hexagonal boron nitride (h-BN), has high potential for hot spot thermal management. We focus on the use of 2D materials as heat spreaders to control temperature of hot spots in portable electronics. We developed a process to transfer h-BN from its growth substrate to an arbitrary substrate (e.g., on a silicon chip) that does not alter the thermal properties of the h-BN significantly and that can be compatible with the industrial processes. We investigate the impact different transfer processes can have on the thermal conductivity of h-BN and benchmark our thermal management solution against current solutions using ultra-fast thermal imaging techniques and simulations.

Fig. 5 SEM microscopy of surface of pristine multilayered h-BN.

Relevant Publications

1. Amitav Tikadar, Nitish Kumar, Yogendra Joshi and Satish Kumar. “Coupled Electro-Thermal Analysis of Permanent Magnet Synchronous Motor for Electric Vehicles”. 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), pp. 249-256, 2020.

2. Amitav Tikadar*, David Johnston*, Nitish Kumar, Yogendra Joshi, and Satish Kumar, “Comparison of Electro-Thermal Performance of Advanced Cooling Techniques for Electric Vehicle Motors,” Applied Thermal Engineering, 183(2), 116182,2020. (* indicates equal authorship)

3. Matthew, R., Manickaraj, K., Sullivan, O., Mukhopadhyay, S. and Kumar, S., “Hotspot Cooling in Stacked Chips using Thermoelectric Coolers,” IEEE Transactions on Components and Packaging Technologies, 3 (5), 759-767, 2013.

4. Sullivan, O., Alexandrov, B., Mukhopadhyay, S., and Kumar, S., “3D Compact Model of Packaged Thermoelectric Coolers,” ASME Journal of Electronic Packaging, 135, 031006, 2013.

5. Sullivan, O., Gupta, M. P., Mukhopadhyay, S., and Kumar, S., “Array of Thermoelectric Coolers for On-Chip Thermal Management,” ASME Journal of Electronic Packaging, 134, 021005, 2012.

6. Gupta, M., Sayer, M., Mukhopadhyay, S., Kumar, S., “Ultrathin Thermoelectric Devices for On-Chip Peltier Cooling,” IEEE Transactions on Components and Packaging Technologies, 21 (9), 1395-1405, 2011.

Funding: NSF