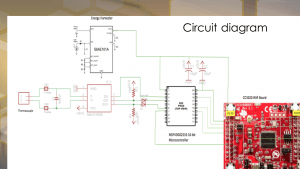

The team used the Type K Thermocouple sensor, MAX31855, MSP-EXP430G2 Microcontroller, Energy harvester, PV cell, and CC3100 Wi-Fi board. The following Diagram show the general topology of the design.

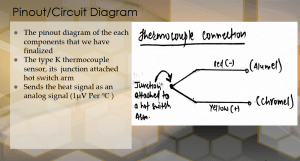

Type K Thermocouple Sensor

A thermocouple sensor works on the principle of Thermos Effect, which states that when the junction of two dissimilar metals is exposed to a thermal gradient, a voltage proportional to the temperature is observed between the two metals as shown in figure 2. These voltages observed is usually on the order of microvolts from which the temperature can be determined. Since the sensor had to encounter a high temperature, we decided to use a type K Thermocouple as they offer large temperature ranges of -200˚C to +1350˚C and low cost.

Thermocouple Amplifier MAX31855 Breakout Board

It compensated Thermocouple-to-Digital Converters perform cold-junction compensation and digitize the signal from the type K thermocouple described above. The output of the MAX31855 will be connected to the MSP-EXP430G2 microcontroller through pins five, six and seven. Pin five (SCK) describes the Serial-Clock Input the clock of the MSP-EXP430G2 microcontroller, Pin six (CS) describes the Active-low Chip select. Setting MAX31855 to the CS mode will enable it to interface with the MSP-EXP430G2 microcontroller. Pin seven (SO) is the Serial- Data Output of MAX31855 .

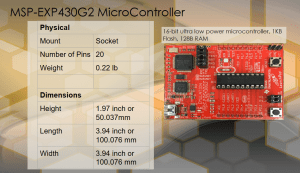

Microcontroller

MSP-EXP430G2 16-bit Texas instruments microcontroller which, is designed for ultra-low power consumption. The microcontroller will enter the interrupt service routine (ISR) every ten minutes by setting the clock frequency from the oscillation frequency and the ISR frequency is set by the clock frequency. The microcontroller will extract the digital signal from the MAX31855 at a rate of the ISR frequency. The measured value from the MAX31855 will be converted to a current value inside of the timer ISR. Finally, the ISR will transfer the current data to CC3100 Wi-Fi board, which connected to it.

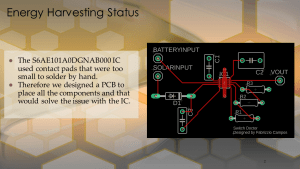

Energy Storage and Harvesting

For the system to function, every component must be powered. The microcontroller works as a distributed power system that powers all the other functionalities of the system; however, the MSP-EXP430G2 microcontroller must first receive power. Through a three-step process, energy can be environmentally harvested and transferred into the MSP-EXP430G2 microcontroller. First, the energy harvested from the sun using Photovoltaic cells. Small solar cells is very low power, delivering mill-watts of energy; therefore, as much of it must be stored. The FYD-004 deliver a max output voltage of 2.2V and max current of 0.68A; however, these values are under ideal conditions. Secondly, in order to get enough power the team used the PCAP0050-P230-S01 super-capacitor to store energy that is harvested by the solar panels and discharges periodically when the MSP-EXP430G2 microcontroller needs to be powered. Lastly, a buck-boost converter used to deliver a constant voltage into the super-capacitor from the solar panel due the irregularity of the energy harvested.

For Communication

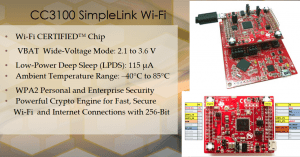

The CC3100 low-cost, low-power microcontroller (MCU) to the internet of Things with the external antenna is used. The CC3100 device is the industry’s first Wi-Fi CERTIFIED chip used in the wireless networking solution. The CC3100 device is part of the new SimpleLink Wi-Fi family that dramatically simplifies the implementation of Internet connectivity. The CC3100 device integrates all protocols for Wi-Fi and Internet, which greatly minimizes host MCU software requirements. With built-in security protocols, the CC3100 solution provides a robust and simple security experience.

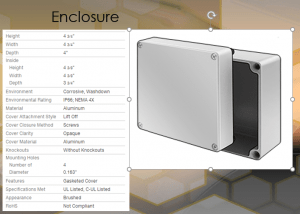

Enclosure

IP66 rating is considered to be dust tight and protected from any jets of water, including any heavy rainfall the prototype will have the following dimensions to be certain that all the components will fit and that we have various options with mounting the components inside A few modifications will still be made to the enclosure itself.