On this last day of the National Week of Making 2022, here is a spotlight on a Georgia Tech Freshman from Savannah, GA Hilmy Rukmana. During Spring 2022, he was awarded the best new Prototyping Instructor (PI) for the Invention Studio at Georgia Tech. Hilmy became a provisional PI in Fall 2021 and quickly rose to become a CNC master in Spring 2022. We talked with him to learn about his interests and aspirations.

Why did you choose Georgia Tech?

Why did you choose Georgia Tech?

Its location in Atlanta. A university with a bounty of great professors, courses, and resources is nothing without an equally bountiful city to fully utilize the students, research, and development produced by Tech. Also, Tech was ranked #2 in undergraduate ME, and it was close to home.

- Tell us about your latest project… why did you build it?

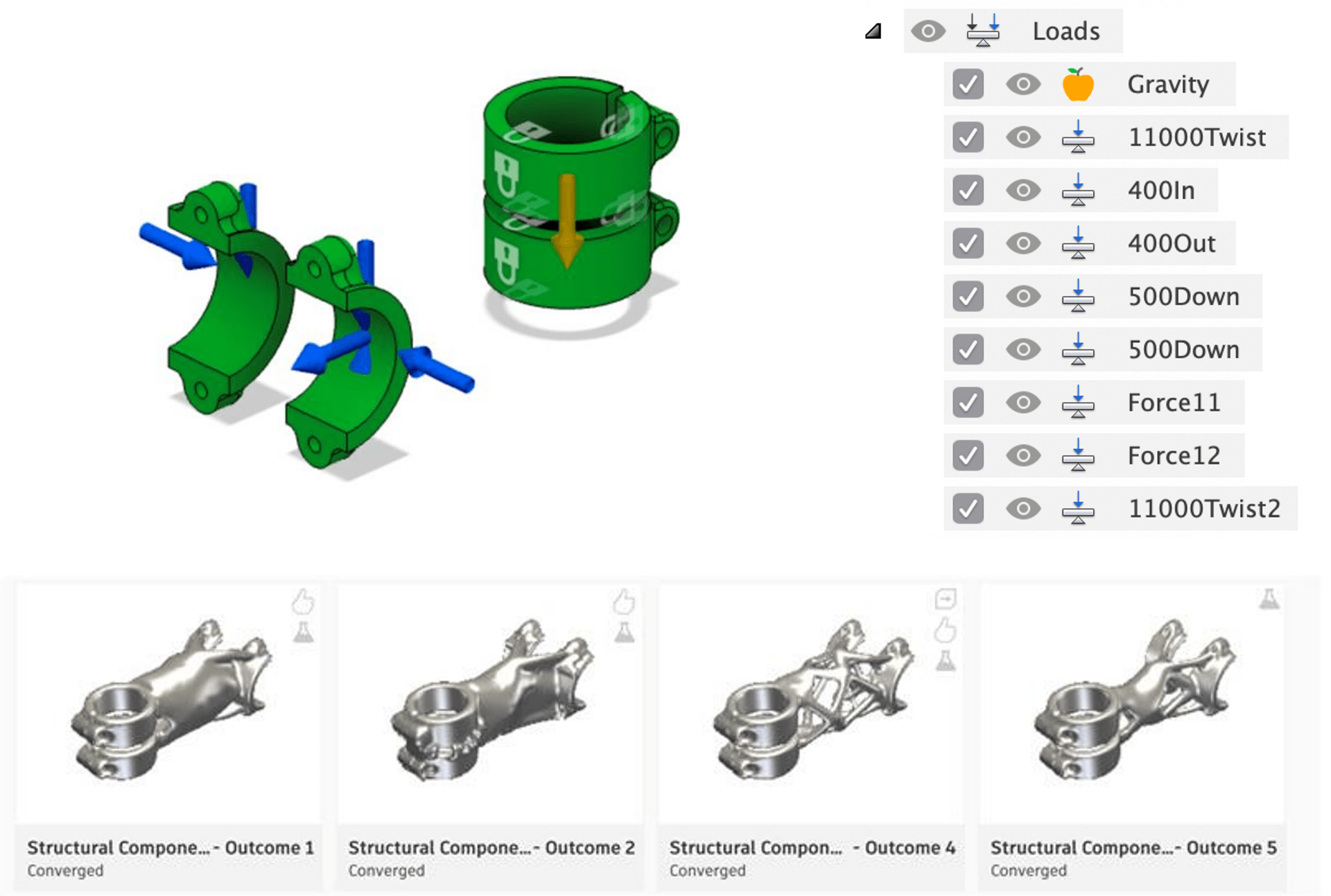

I had nothing to do for a weekend and always had this on the backburner. I needed a new bike stem and was bored at the lack of design diversity with the stems currently on market. I was curious about how powerful generative design was. I wanted to push my machining knowledge to its limit, combining 2D and 3D toolpaths outside of simple adaptive and parallels, and creating setups to utilize a ‘poor man’s 5th’ Since we do not have a fourth axis attachment for the EMCO and our current one for the Tormach is down, I had to manually rotate the stock to machine all four sides and decided to machine the top side for extra detail and fidelity, making it a 5 axis milling operation.

- What tools/equipment and software did you use for the project?

I used AutoDesk Fusion 360 to design the project. I self-taught myself Fusion 360 during Fall 2021 before I switched to ME. It was incredibly user-friendly, the user base online is much much larger than SolidWorks, so I could ask literally any question and there would be an answer online. Furthermore, it’s cloud-based so I could guarantee that none of my CAD or CAM setups would ever be lost. Its generative design workspace is also incredibly powerful (in comparison to SolidWorks) and far more user-friendly. I also recently accepted a position to start an ambassadorship for Autodesk starting Fall 2022. I used the EMCO E350 CNC Machine and the Sandblaster for building the part.

- What do you aspire to do while at and perhaps beyond GT?

I hope to perform outstandingly with my group when I take ME 2110 in Fall 2022, delve into manufacturing methods and designs for my fourth-year capstone project, and hopefully join a company that creates for creators, that makes for makers. In other words, I want to join a company that researches and develops machines and manufacturing methods to help others create more things. Great ideas are nothing without the tools to realize them. A few companies that come to mind are Formlabs, Tormach, Ultimaker, and Mazak.

- What do you think would be the future of making and/or education?

Manufacturing wise, I believe the future is a fusion between additive and subtractive, where the bulk of the product is produced as materially-efficient with additive but made dimensionally accurate with subtractive. More generally, the future of making is everyone making. No matter their skill or passions, whether it’s metal CNC, woodturning, or embroidery, making is making, and you can’t stop making. It’s addictive, fun, and productive. Education wise, we need more pre-university schools affording their students the tools to make stuff. Not necessarily 3D printers or fancy STEM equipment, but a simple paint set would do. The power given to a child when they have a tool to turn funky brain ideas into funky real things is immeasurable and powerful.