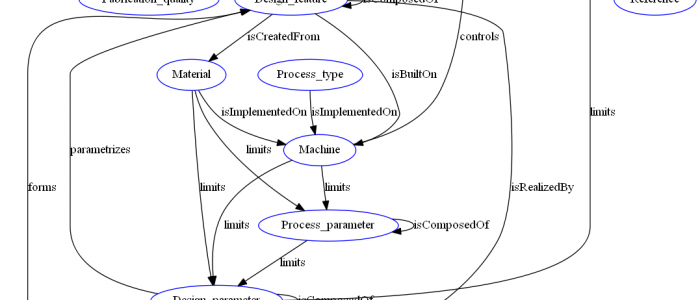

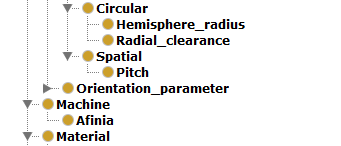

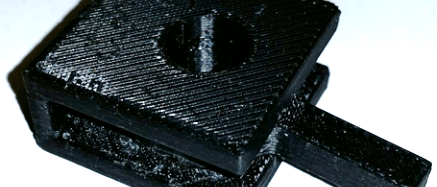

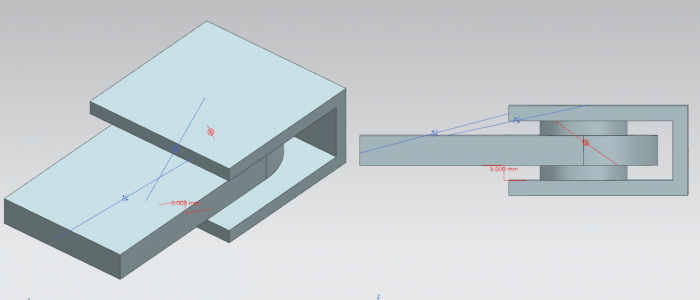

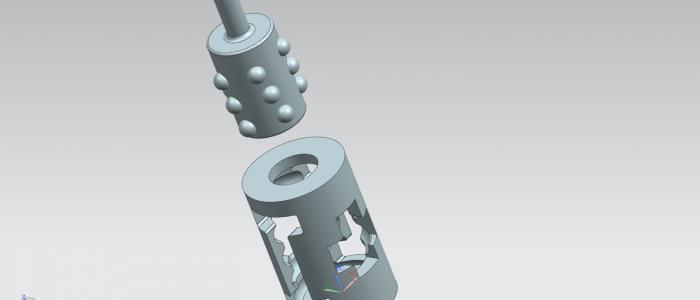

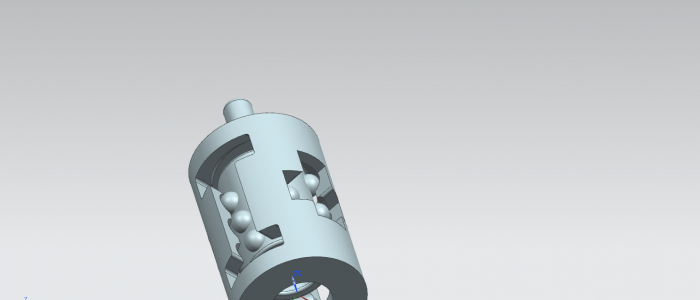

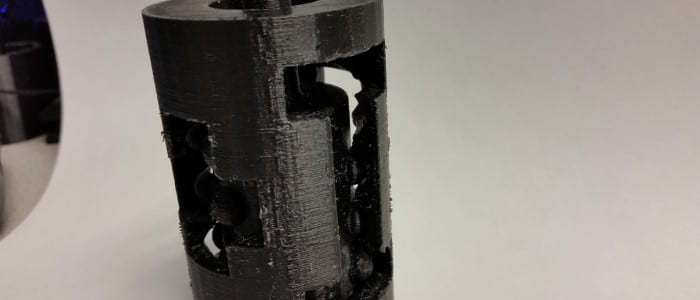

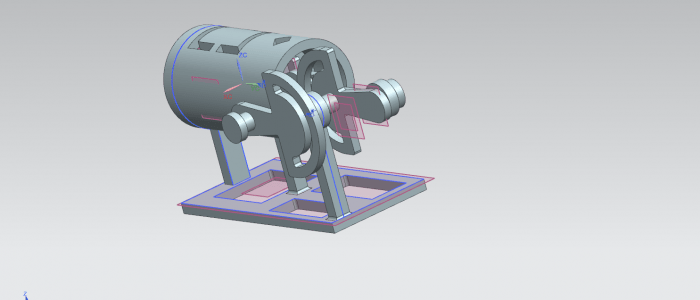

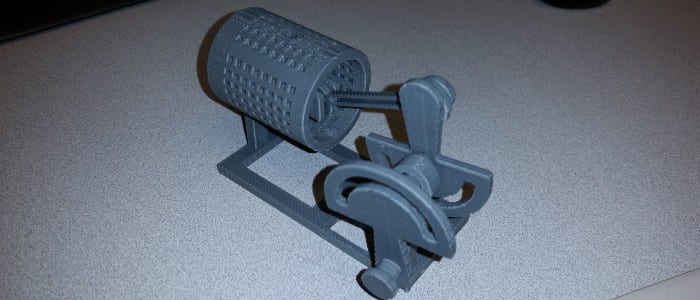

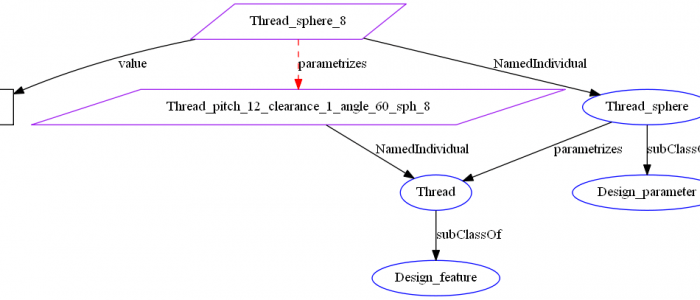

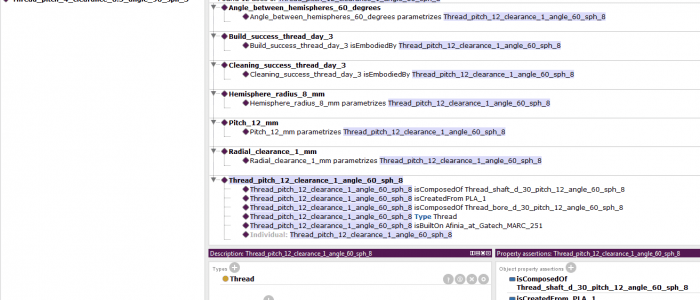

Design for additive manufacturing gives designers new freedoms to create complex geometries and combine parts into one. However, it has its own limitations, and more importantly, requires a shift in thinking from traditional design for subtractive manufacturing. Unlike traditional manufacturing techniques where process planning is fairly established, there is a lack of formal and structured guidelines on how to apply additive manufacturing, benefit from it, and understand its limitations, especially for novice designers. In an effort to formalize knowledge of design for additive manufacturing processes, we have developed an ontology using formal RDF and OWL representations in the Protégé tool. The knowledge is represented in terms of a set of subjects (abstract entities), object properties (relations or links among the entities). The subjects have a hierarchical structure where subclasses have a standard RDF:isA relationship with the superclass. This formal modeling approach also includes defining data properties (attributes of entities), cardinality rules, types of object properties (e.g., symmetric or directional relations), properties of subject sets (e.g., an entity being disjoint with other entities under a superclass), and cardinality rules. We demonstrate how information about building three types of design features were instilled in different modeling attempts. The features are revolute joint, thread assembly (screw connection), and slider-crank. How multiple instances (build events) are stored and retrieved in the knowledge base is discussed in light of different modeling decisions that were made in different versions of the ontology. A set of competency questions are described which help evaluate the sufficiency of the ontologies. Examples are given about how queries are formalized in SPARQL (the formal querying language for semantic web) and what can be retrieved. The formalized ontology not only provides a way to capture and describe meta-knowledge about design for additive manufacturing, but also creates a basis for documenting the existing ad-hoc information in the literature on guidelines for how to utilize the different additive processes and what their limitations are. Knowledge documentation is the main objective of the current ontology. However, representation of design rules in a structured modular hierarchy, and reasoning about these rules in addition to discovering new rules (e.g., generalizations with induction) are future directions and considered when modeling current ontologies.